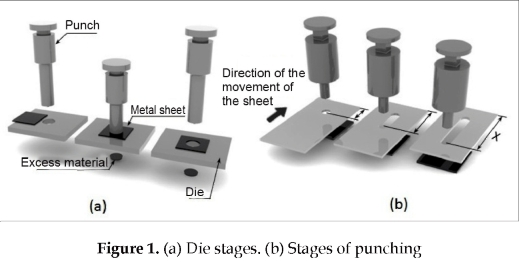

In blanking the punched out piece is used and called a blank.

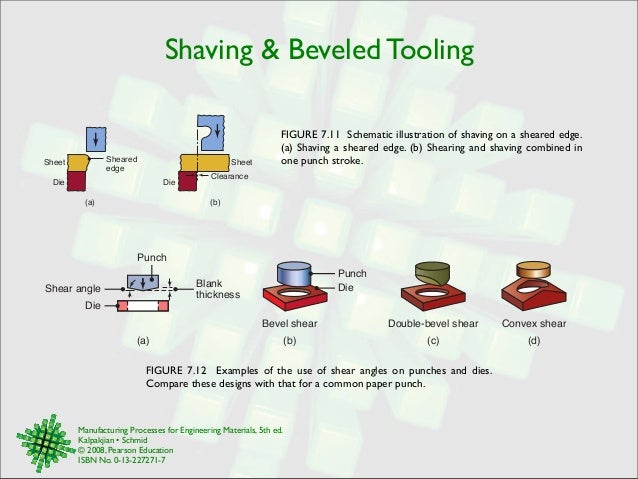

In sheet metal blanking operation the shear is provided on punches and dies so that.

In piercing the punched out piece is scrap.

It force applied by the blanking punch impact the sheet metal and sheared the blank into die opening.

In case of piercing or punching the material which is cut out from the sheet metal is scrap and the reining material is the actual part.

In sheet metal work he cutting force on the tool can be reduced by 4.

Blanking and piercing operations can be performed simultaneously in a 3.

As i said earlier both are metal shearing operations used for cutting sheet metal.

Both blanking and piercing are shearing operations.

Difference between blanking and piercing.

The blanking operation perform at slowly.

The tooling and processes are the same between the two only the terminology is different.

In sheet metal blanking shear is provided on punches and dies so that a press load is reduced b good cut edge is obtained c warping of sheet is minimized d cut blanks is straight 2.

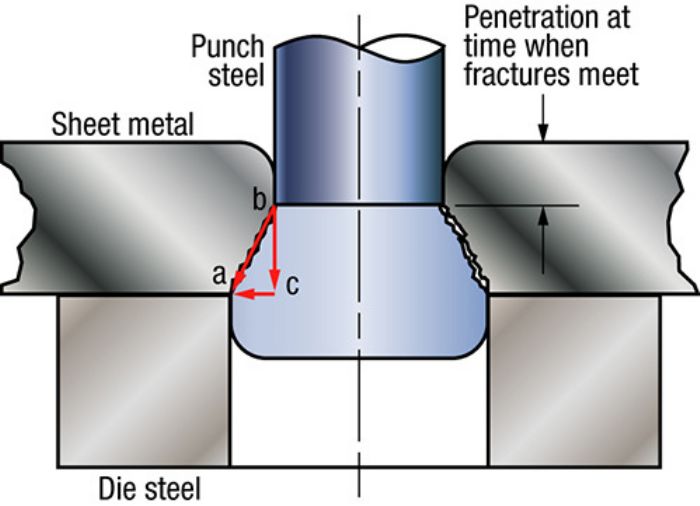

The clearance provided in between punch and die the range of 0 001 inches.

The major differences are as.

In sheet metal blanking shear is provided on punches and dies so that 3147382.