Material selection is done based on product functional requirements by looking at material physical and mechanical properties.

In sheet metal operations the volume of material.

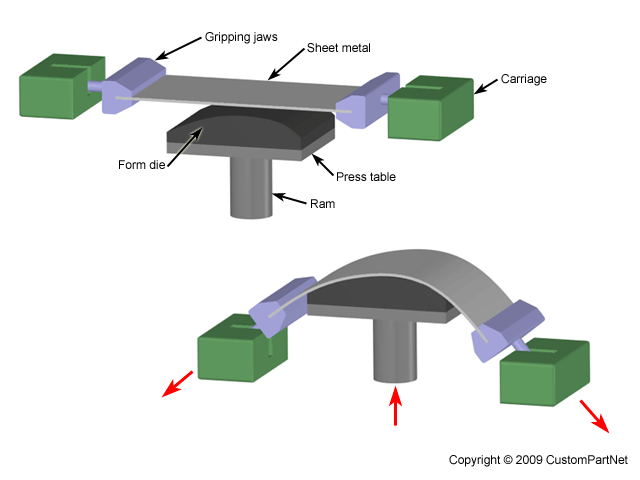

By doing so the sheet can be bent or stretched into a variety of complex shapes.

A elastic region or b plastic region.

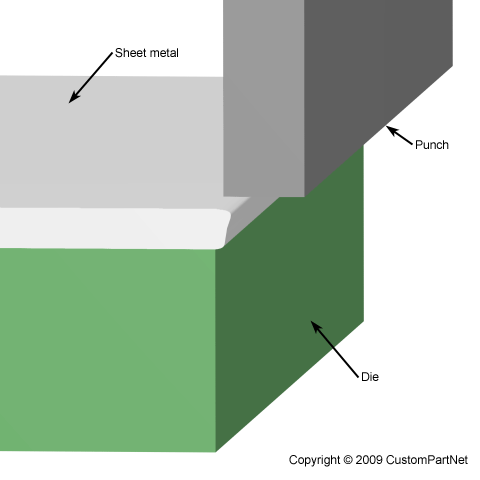

Both punch and die are also applied in this operation.

Following are some of commonly.

Firstly sheet metal products usually have low prototype volume and high production runs which makes the fabrication very cost effective because of large initial set up as well as material costs.

Mishra in friction stir processing for enhanced low temperature formability 2014.

Various sheet metal material grades are available in the market.

It is customary to refer to a material below the thickness of 6 35 mm as a sheet and thicker materials as plate.

The punch used in the piercing operation is usually bullet shaped.

Press working operations or sheet metal operations.

Sheet metal forming is quite common for making shaped components from soda cans to automotive car bodies.

The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

By physical removal of the material from the sheet if the required shape of the component is obtained called as cutting or shearing.

Mainly sheet metal process can be divided into three types.

Low volume to area ratio 14 5 the flow curve expresses the behavior of a metal in which of the following regions of the stress strain curve.

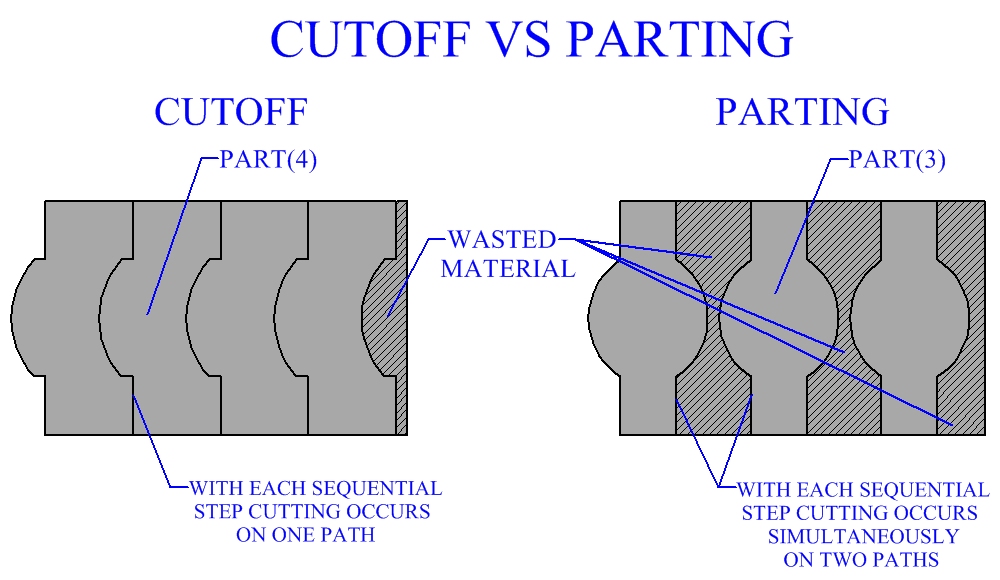

Shearing is the process of separating the sheet metal into two or more pieces normally by cutting along a line.

Piercing is the process in which desired shape holes are produced in a piece of sheet metal without eliminating any material from the sheet or removing a very small amount of material as shown in the figure.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing in this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material.

Type of rolling operation hot rolling or cold rolling operation also has an impact on sheet metal material properties.

Simply put cutting operations cause the sheet metal to be stressed beyond its ultimate strength therefore breaking its structure and separating into different parts.

The detailed info about 5 9 sheet metal operations are presented at the end of the article and the rest 1 4 are covered at the beginning of the article.

14 4 which of the following is typical of the starting work geometry in sheet metal processes.

Sheet metal fabrication process is not like any other fabrication.

Cutting and forming thin sheets of metal usually performed as cold working sheet metal 0 4 1 64 to 6 mm 1 4in thick plate stock 6 mm thick advantage high strength good dimensional accuracy good surface finish economical mass production low cost.