They have daily duties such as fastening metal seams welding bolting creating supportive frameworks taking measurements and maneuvering material around.

In sheet metal work the knowledge of following is essential.

Sheet metal fabrication is the act of forming shaping and joining metal together to build and or repair a tangible part.

Only the main difference is that the hole is the desired product and the material punched out to form a hole is considered as a waste.

To assist in tutorial work in these courses worked examples are.

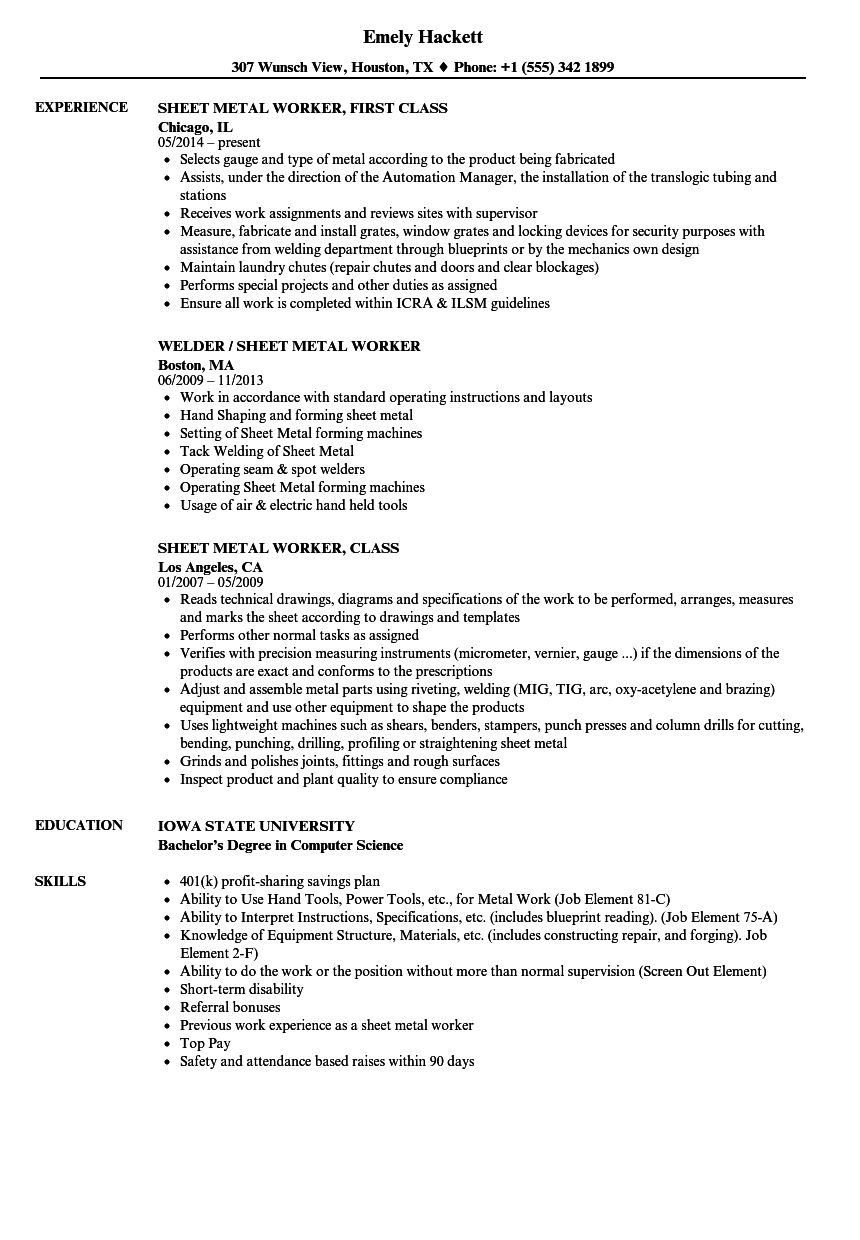

A sheet metal worker is a skilled tradesman who creates installs and repairs sheet metal products.

The aim is to bring students as quickly as possible to the point where they can analyse simple cases of common processes such as the forming of a section in a typical stamping.

Sheet metal workers use saws lasers shears and presses.

There are many different metals that can be made into sheet metal such as aluminium brass copper steel tin nickel and titanium.

Setting up and operating fabricating machines to cut bend and straighten sheet metal.

Vocational education courses such as blueprint reading mechanical drawing and welding are also helpful.

You can find sheet metal in the form of foil as well.

Most commonly these products include elements of heating cooling and ventilation systems although sheet metal workers also fabricate and repair products for drainage and roofing applications.

It is similar to blanking.

Its thickness is quantified by a measure known as its gauge.

Some sheet metal workers are skilled tradesmen while others work on assembly lines performing less skilled tasks of metal assembly.

Sheet metal workers must calculate the proper sizes and angles of fabricated sheet metal to ensure the alignment and fit of ductwork.

Sheet metal workers are responsible for installing and sometimes fabricating thin metal sheets used in a variety of applications.

There are many techniques and tools.

It s been done since the beginning of time when even the simplest tools were used.

Parts manufactured from sheet metal must maintain a uniform thickness for ideal results.

Sheet metal workers typically need a high school diploma or equivalent.

Shaping metal over anvils blocks or forms using hammer operating soldering and welding equipment to join sheet metal parts inspecting assembling and smoothing seams and joints of burred surfaces.

1 what is punching operation.

Sheet metal engineers and mechanical metallurgists in industry and particularly in the automotive field.

Those interested in becoming a sheet metal worker should take high school classes in algebra and geometry.

A wide range of products are manufactured with the use of sheet metal making it an essential part of the modern world.

It is the cutting operation with the help of which various shaped holes are produced in the sheet metal.

There are many techniques and tools.

Work may involve any of the following.

Sheet metal process.

Sheet metal workers can also work in.

Sheet metal varies in thickness.